NASA battery safety exams influence commercial product testing

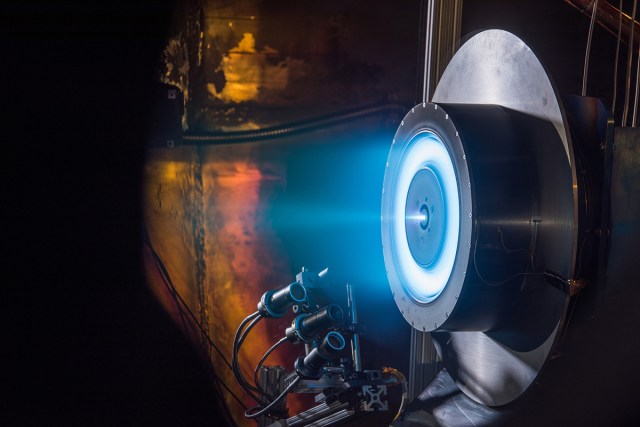

Battery safety is of paramount importance in space, where the risk of thermal runaway looms large. This dangerous reaction, characterized by a continuous escalation of temperatures within the battery, can potentially lead to a fire or explosion.

For two decades, Judy Jeevarajan was the NASA engineer in charge of testing. Thanks to that experience, batteries for everything from industrial equipment to home appliances are tested using methods she originally developed for spaceflight.

Jeevarajan began working at NASA’s Johnson Space Center in Houston in the 1990s, developing advanced battery testing technologies, eventually becoming responsible for approving all batteries flown for human spaceflight. In 1999, shuttle astronauts wanted to bring a digital camcorder aboard. Previous video cameras on the space shuttle used battery chemistries already authorized for space, but the emerging use of lithium-ion cells was new territory for space missions.

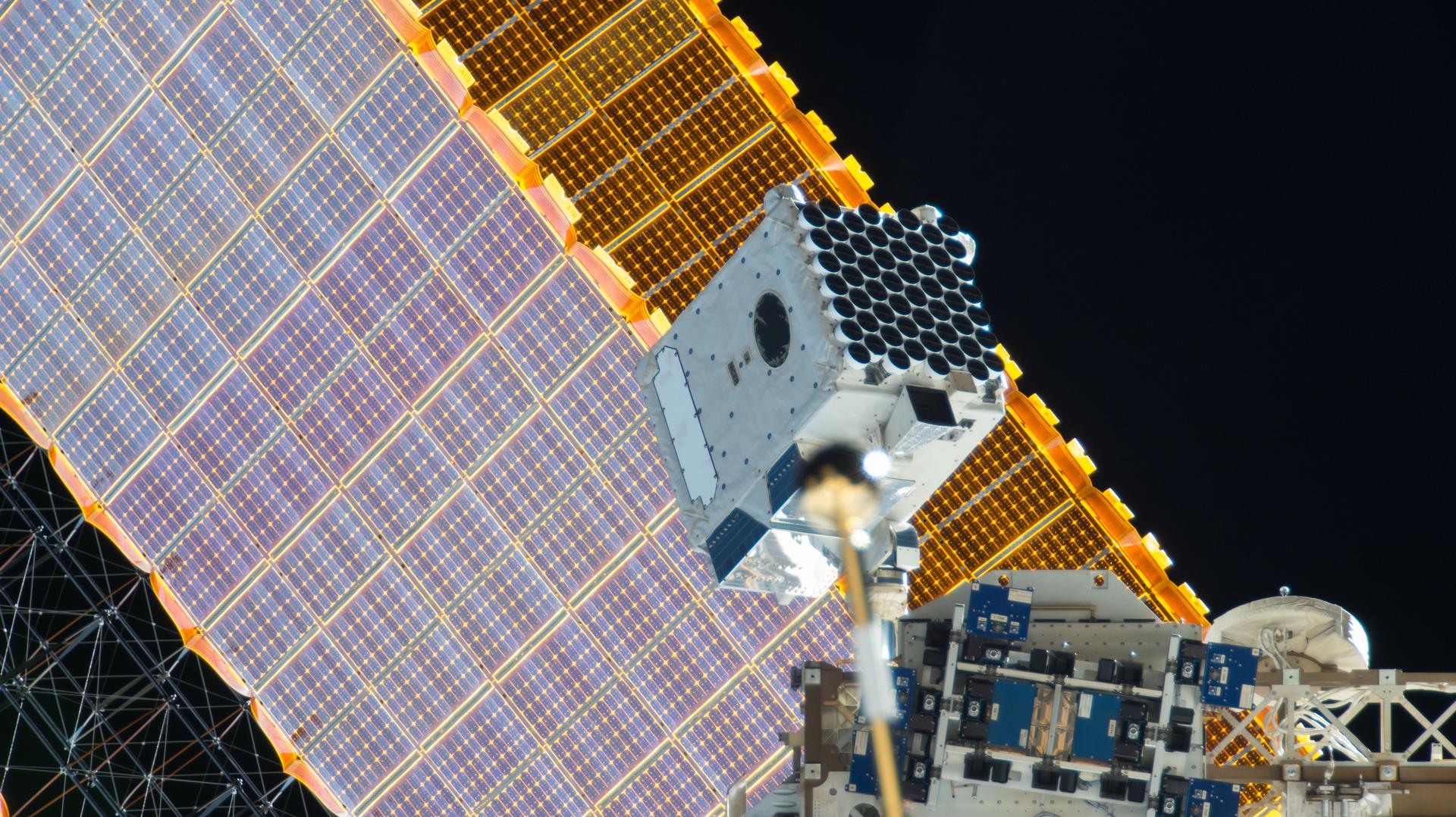

To test these batteries, her team used a hydraulic press to test the tolerance to internal short circuits and they devised a vibration test that would ensure the intense shaking at launch wouldn’t lead to failure. After the camcorder’s lithium-ion batteries were approved to fly, her work expanded to testing batteries for every consumer-grade device brought aboard the International Space Station.

For more than 100 years, Underwriters Laboratories Inc. (UL) of Northbrook, Illinois, has developed standards and testing modes for all modern appliances and technologies, ensuring everything is as safe as possible. After Jeevarajan met engineers from UL at a battery safety conference, she became a member of the UL Standards Technical Panel for battery safety. Over the next decade, she helped verify the workings of a new battery-testing machine and used her NASA experience as UL further developed and promoted the adoption of new testing methods.

Jeevarajan joined UL’s nonprofit arm full-time in 2015, bringing with her decades of experience gained working at Johnson, including her techniques for inducing thermal runaway. These are now part of a UL-defined test method for testing cells in large lithium-ion battery systems, like those found in batteries for storing power on the electrical grid.